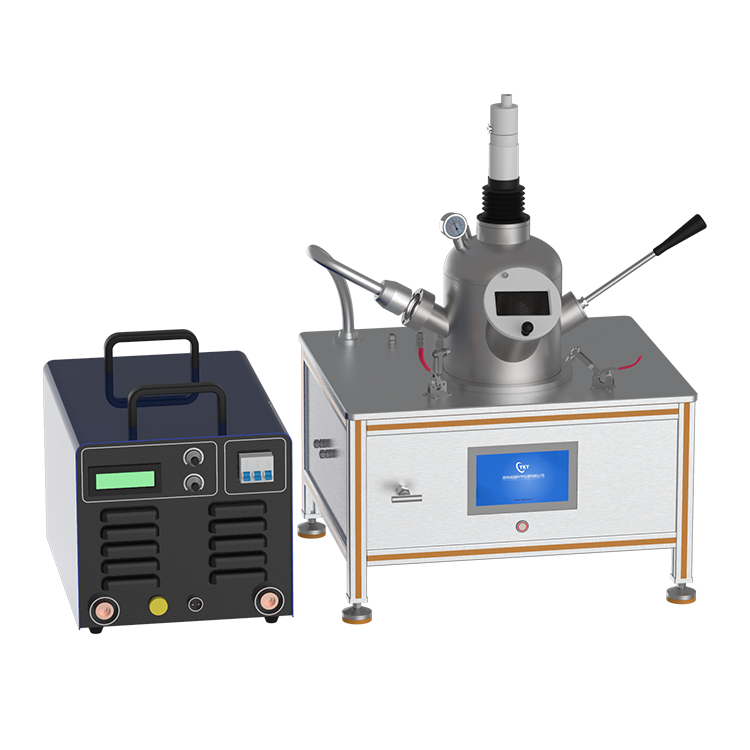

1. Power supply: AC380V 50Hz (optional) 2. Overall power: <10KW (optional) 3. Vacuum chamber: Ø200mm × 300mm 4. Crucible: 7 Standard crucibles, size: φ25 (melting capacity: 15g stainless steel) Suction casting sample: φ6 (melting capacity: 15g stainless steel) The following are optional: One 50g crucible, size: φ40x20 (melting capacity: 50g stainless steel) 4 φ25x12.5 (smelting capacity: 20g stainless steel) Another suction casting sample: φ10x75 (melting capacity: 15g stainless steel) 5. Some accessories can be changed for 50g stainless steel sample melting and casting (the melting current needs to reach 300A) 6. Vacuum degree: When equipped with our molecular pump, it can reach 1E-5mbar, and rotary vane pump can reach 1E-3mbar (the diffusion pump can also be configured by yourself to obtain better vacuum) 7. Non-consumable arc starting electrode: tungsten needle (W) 8. Scope of application: It can be used for smelting metal materials with a melting point lower than that of tungsten metal. 9. Melting temperature: up to 3000℃, it can melt almost all metals   4.5g metal tungsten sample 10g metal tungsten sample 10. Output current: 20-315 (A) |